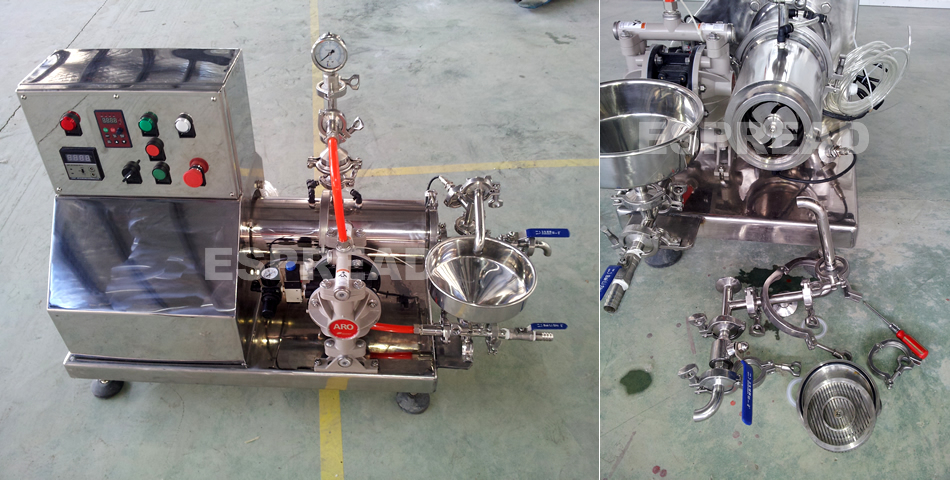

Product Introduction

Pilot Horizontal Bead Mill is a Fine Grade continuous wet grinding equipment for labs of collages and research institutes.?It is suitable for mid-batch test for biology, pharmacy, cosmetic, food, paint, ink, color paste and other chemicals.

Material viscosity: <=50,000 cps

Production Capacity: 3-30 L

Application Fields: Suitable for dispersing, grinding materials in a variety of applications such as biology, pharmacy, cosmetic, food, paint, ink, color paste, dyestuff, fertilizer etc.

Applicable materials: Good for Materials with viscosity less than 50000cps, with comparatively high requirements of final fineness, such as automobile paint, color paste, water-based ink, fertilizer suspension, lithium battery slurry etc.

Working Principle

The diaphragm circulates the materials in the grinding chamber. The main shaft in the?grinding chamber is equipped with many pins with high anti-abrasiveness and hardness. The pins drive the grinding medium inside the grinding chamber to irregular movements in all direction to put the materials under the action of constant collision and friction. At same time, the materials are separated from the grinding medium by the sieve and keep circulating from the tank to the grinding chamber to obtain smaller particle size, narrower particle size range.

Main Feature

Auto digital instant temperature display

Integrated double mechanical seal

Full stainless steel frame body

Quick assembly and dissembly

Ingersoll Rand diaphragm pump

| Model | Power | Speed | Chamber volume | Grinding media | Voltage |

| ESWS-2 | 2.2kw | 0-2000rpm | 2L | 0.8-2.0mm | 220V/50HZ |

1. discuss full requirement with our sales engineers

2. sending official quotation based on requirements

3. order confirmation mutually

4. arrange deposit payment according to the order

5. arrange production at our factory

6. arrange the final payment

7. arrange shipping and logistics

8. machine received confirmation

9. installation and commissioning if needed

10. order complete and aftersales